-

Antal inlägg

96 -

Gick med

-

Senaste besök

-

Dagar vunna

9

Typ av innehåll

Profiler

Forum

Kalender

Galleri

Saltvattensguiden.se ideell förening dokumentportal

Bloggar

Frågesport

Inlägg postat av Jonesyg

-

-

-

-

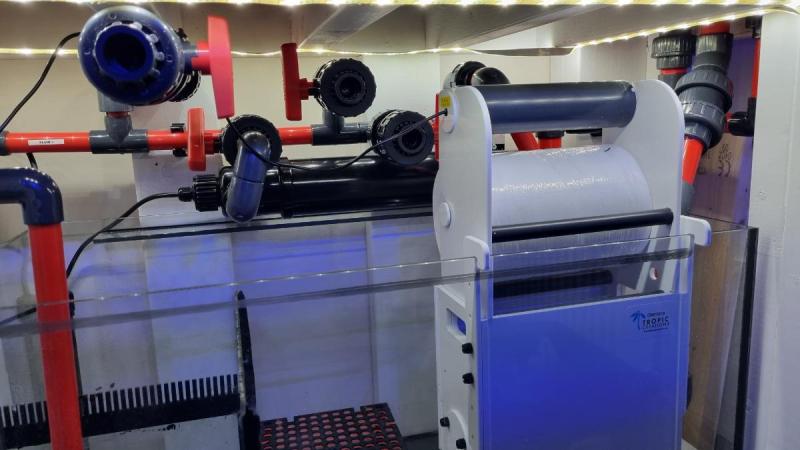

Now the tank has been filled with water at last! Some changes to the sump was needed to get the correct water height for the roller filter. I will move some live rock and bio balls from the 250 system across and hopefully start transferring fish in a few weeks. When the 250 is empty I can then start moving across the Apex systems and fixing the electrical cabinet.

Still lots of work to do in both the office and fish room !

-

4

4

-

-

-

-

-

Work has started on the plumbing today, starting with the return pipework. Added valves for frag tank, reactor and one spare. I also added connection points for the UV system.

My previous tank had the UV feed draining to the sump, this time I will try it plumbed back into the return to the tank, adding a valve after the UV to regulate the flow and not create negative pressure over the bulb.

I will also add a fixed pipe from my mixing station for easier water changes

-

4

4

-

-

-

-

-

-

-

-

-

-

Tank has arrived, big thanks to @Deividasbörjare2 for the help with delivery and smooth purchase!

-

2

2

-

1

1

-

-

With the go ahead from management I can now start my dream project!

This is my build thread for my new 550 litre peninsula wall tank build.

I will be building the tank into the wall between the wash room and my office, currently I have a reefer 250 and a frag tank which I will move livestock and equipment across from to the new tank.

I will post updates throughout the build, comments and suggestions are welcome!

-

5

5

-

Gregs peninsula wall tank build

in 151-720 liter

Postat

@MichaelE @stigigemla I was very tight on space in the end so it ended being the only place for it, the sump area ended up being smaller than I wanted due to the height requirement of the tank on the other side of the wall. I pushed through max flow a few times to try and clear any trapped air but there is probably some stuck at the end of course. If it becomes an issue I can always re do that section of plumbing, I have extra valves prepared also for future additions.