norskfisk

Medlem-

Antal inlägg

37 -

Gick med

-

Senaste besök

-

Dagar vunna

3

norskfisk vann senast den december 11 2021

norskfisk hade det mest gillade innehållet

Profilinformation

-

Förnamn

Jon Olav

-

Stad

Norge

-

Akvarievolym

320

-

Ljusuppsättning

T5 lysrör

-

Använder du skummare

Nej

-

Mitt huvudsakliga intresse för karet är

Kemi och biologi

-

Använder du Osmosvatten

Nej

-

Har du sump

Nej

-

Kör du med sand på botten

Ja

-

Använder du UV-C

Nej

-

Använder du Ozon

Ja

-

Använder du zeolitbaserad metod

Nej

Senaste besökare

Detta fält är avaktiverat av användaren.

norskfisk's prestationer

-

Ja, Chihirosen har app med programmeringsmulighet. Har lest mye om akvariedatamaskiner opp igjennom årene. Men det frister meg rett og slett ikke å sitte å debugge de greiene. Arduinoen derimot syntes jeg var gøy å jobbe med. Det er egentlig det viktigste. Så utrolig enkel og akkurat det jeg trengte. Komponentene er nesten gratis (hvis de ikke brenner ned huset selvfølgelig ). Det gikk så bra med bølgekontrolleren at jeg satte i gang med en foringsautomat med innebygget kjøleanlegg for å holde maten kald. Håper på å ha den klar når planktonsesongen begynner til våren. Da kan jeg ha anemoner, skjell og sjøpunger.

- 31 svar

-

- kallvatten

- jon-olav

-

(och 1 mer)

Taggade med:

-

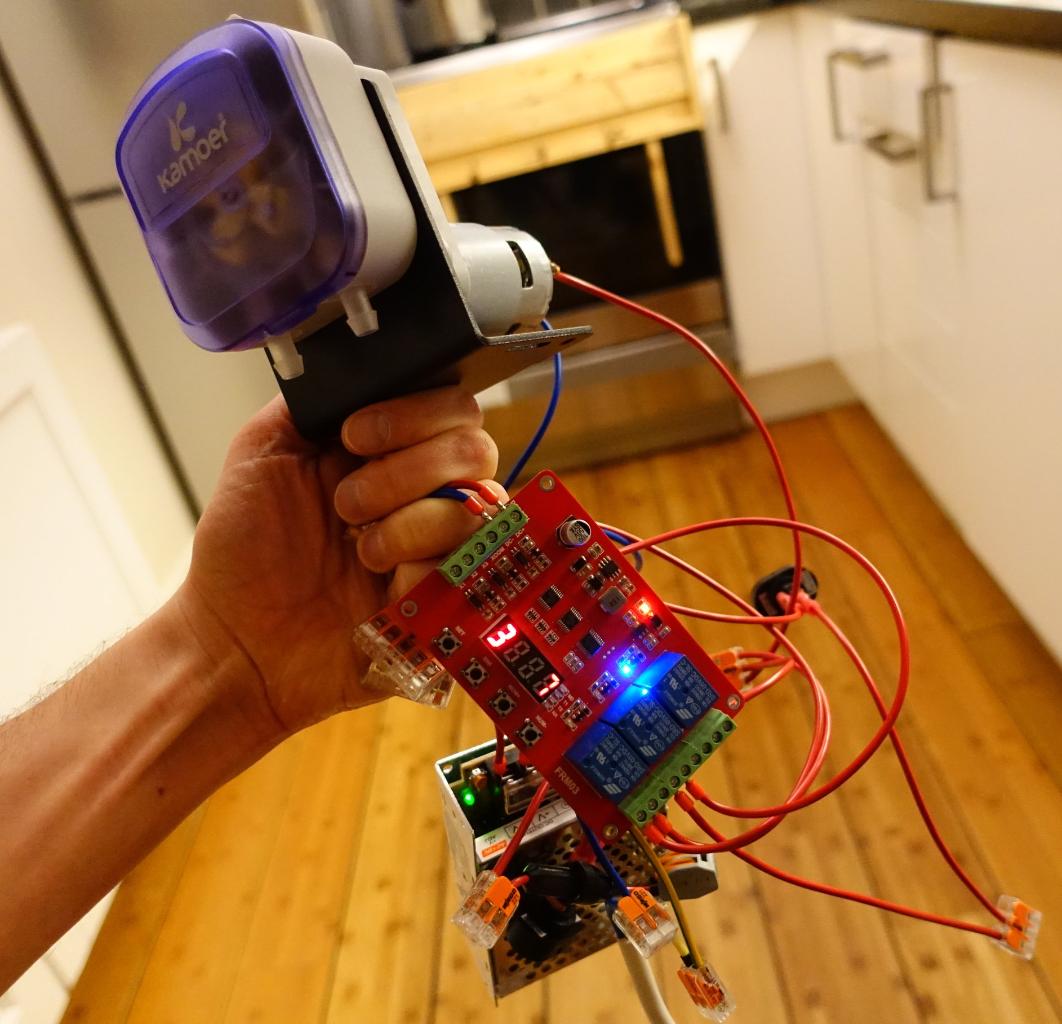

Her er noen bilder av utstyret: 1. DIY bølgekontroller i aluminiumsboks for brannsikkerhetens del. 2. Innsiden av DIY bølgemaskin: Arduino, Strømforsyning, releer, Jebao kontrollere. 3.UV filter 4. Ozonsystem 5.AmTop 3338 utvendig filter og lydisolert kasse for kjøleanlegg 6. Hele systemet i stuen.

- 31 svar

-

- 2

-

-

- kallvatten

- jon-olav

-

(och 1 mer)

Taggade med:

-

Jeg bruker vanlig digital timer fra ClasOhlson til å styre lyset, og så setter jeg daglengden manuelt 0 til 3 ganger per måned. Kelvin: Bruker til enhver tid 50% Sylvania aquastar 10000K og 50% Sylvania Grolux planterør. Vet ikke helt hvilken Kelvin planterørene er. Jeg har kjøpt en Chihiros Vivid 2 LED lampe på 130 Watt (har ikke brukt den ennå). Til våren planlegger jeg å bruke kun den. Den har app kontroll med soloppgang/solnedgang funksjon og intensitets- og fargekontroll. Da tenker jeg å bare bruke den. Den er spesiallaget for planteakvarier. Ja, det er 3 Jebao SOW-8 på hver side av akvariet, 6 totalt. Den medfølgende kontrolleren står på konstant flyt, styrkenivå 2 (av 10 tror jeg), på alle pumpene. De styres med en DIY kontroller som lar den ene siden stå på i 13 sekunder, 3 sek pause, den andre siden på 13 sekunder og 3 sek pause. Skal ta et bilde av kontrolleren. Den er ikke noe vakkert syn, men den har funger 100% i mange måneder. Sagtangen vokser bra. Jeg må trimme den ned. Men den trives ikke 100%. Den blir stiv og ikke spesielt pen. Når den blir ca 20 cm lang blir den så stiv at strømmen i akvariet ikke klarer å bevege den skikkelig. Jeg tror den trenger kraftigere vannbevegelse enn jeg kan gi. Den kan ha andre behov også som f.eks har med vannkjemi i bølgesonen å gjøre, UV stråling, lysstyrke. Jeg vet ikke. Så den vokser, men forholdene er ikke ideelle. Nei, bruker ikke sump. Jeg bruker et AmTop 3338 utvendig filter. Det tok omtrent 4 måneder, men til slutt forsvant også proteinhinnen på overflaten. Så jeg har mye tro på slikt filter. Eneste problemet er at inntaket må renses hver dag om sommeren.

- 31 svar

-

- 2

-

-

- kallvatten

- jon-olav

-

(och 1 mer)

Taggade med:

-

Takker! Bare spør, gøy å snakke om akvariet mitt Grunnen til at det er så reint nå om vinteren er at brune og grønne trådalgene forsvinner når de merker at dagene blir kortere. De overvintrer i en annen form. Du ser dem ikke i naturen heller på denne tiden av året. Jeg har 6x24 Watt (144 Watt) T5 lysrør. De 2 mørkeste månedene bruker jeg bare 48 Watt De 4 nest mørkeste månedene bruker jeg 96 Watt De 6 lyseste bruker jeg 144 Watt. Daglengdene, styrke, temp, hele året: 04 timer den: 20 jan (33% styrke), 5C 05 timer den: 2 feb (66% styrke), 5C 06 timer den: 13 feb (66% styrke), 6C 07 timer den: 24 feb (66% styrke), 6C 08 timer den: 7 mar (66% styrke), 7C 09 timer den: 18 mar (67% styrke), 8C 10 timer den: 28 mar (100% styrke), 8C 11 timer den: 8 apr (100% styrke), 9C 12 timer den: 19 apr (100% styrke), 10C 13 timer den: 30 apr (100% styrke), 11,C 14 timer den: 13 may (100% styrke), 12C 15 timer den: 25 may (100% styrke), 14C 14 timer den: 17 july (100% styrke), 15C 13 timer den: 12 aug (100% styrke), 16C 12 timer den: 22 aug (100% styrke), 18C 11 timer den: 3 sep (100% styrke), 17C 10 timer den: 13 sep (100% styrke), 16C 09 timer den: 25 sep (66% styrke), 15C 08 timer den: 6 oct (66% styrke), 14C 07 timer den: 17 oct (66% styrke), 13C 06 timer den: 28 oct (66% styrke),12 05 timer den: 8 nov (66% styrke), 10C 04 timer den: 21 nov (33% styrke), 9C 03 timer den: 8 dec (33% styrke), 8C Jeg måler nitrat og ammonium i vekstsesongen. Ellers bytter jeg 50% vann ca 1 gang per 6 uke.

- 31 svar

-

- 2

-

-

- kallvatten

- jon-olav

-

(och 1 mer)

Taggade med:

-

Hei, Doserer plantenæring uten uten nitrogen og fosfor: https://www.cyberzoo.se/sv/articles/2.241.5455/happy-life-happy-plant-500-ml Doserer litt Tropica specialised nutrition (med nitrogen og fosfor): https://tropica.com/en/plant-care/liquid-fertilisers/specialised-nutrition/ Satt opp CO2 tank i sommer, men det blir så håpløst å holde pH-en riktig at jeg gav opp. For høy risiko i forhold til nytte!

- 31 svar

-

- 3

-

-

- kallvatten

- jon-olav

-

(och 1 mer)

Taggade med:

-

Planktoniske børsteormer. Vet ikke så mye om dem. Kan være disse: https://en.wikipedia.org/wiki/Tomopteris

-

Styresystemet heter FRM03 og er en 12V programmerbar timer modul med tre releer som man kan kjøpe for nesten ingen ting på Aliexpress. Man programmerer med knapper og display på selve kortet. I tillegg er det en 12V transformator og en kraftig doseringspumpe som er laget for væsker med små partikler. Også fra Aliexpress.

- 432 svar

-

- 1

-

-

- 432 svar

-

- 3

-

-

God ide med kjøleskapet. Tror det er den beste løsningen for kjøling. Min plan var å ha en beholder med vann som alltid var full og hadde et sikkerhetsoverrenn tilbake til akvariet. Og en kraftig doseringspumpe som pumpet vann begge veier. Først til akvariet for foring, og så tilbake til beholderen for å toppe opp med vann. Så en stor propell som gikk sakte i 5 sekunder før hver foring. Dermed ville det ikke sitte mat i slangen (mat klistrer seg fast i tynne slanger), maten ville ikke bli skadet av stadig omrøring. Og alt jeg behøvde å gjøre daglig var å ha i et par kuber med frossenfor.

-

Det beste ville være å alltid ha litt for i vannet. Jeg planla en automatisk frossenformaskin. Den ble dessverre veldig avansert med innebygget kjøleanlegg, omrøringspropell, doseringspumpe samt datamaskin for å styre hele greien.

- 432 svar

-

- 1

-

-

Det er flere dvergrekearter å velge mellom. Kan også være thoralus cranchii eller eualus pusiolus.

-

Hei folkens, Vi kjøpte nytt hus og flyttet like etter den siste videoen jeg la ut i fjor, så jeg måtte ta ned akvariet som jeg startet i mars i fjor . Etter det har det vært beinhardt arbeid både på jobb og hjemme for å flytte inn med familien. Er sikker på jeg skrudde 1 million Ikea-skruer i 2020. Men nå begynner det å se lysere ut! Skal sette opp igjen samme akvariet i stuen i det nye huset. Har laget en lydisolert boks til kjøleanlegget! Forresten, nytt kjøleanlegg, DD DC-750. Kan aldri ha for mange kjøleanlegg .

-

They are copepods, yes. These are probably in the order harpacticoida. They ate micro algae growing on the glass in my algae refugiums.

-

Hey, the algae are Swedish! Bought on Biltema and Clas Ohlson!

- 31 svar

-

- 1

-

-

- kallvatten

- jon-olav

-

(och 1 mer)

Taggade med:

-

Water gas and other gasses pass through anything with solvent (even water) in it while it dried. You can glue the glass in place with silicone, but use this as a sealant outside: Solvent free windscreen sealant I have actually tested this over several years and seen that it works.

Saltvattensguiden

Organisationsnummer: 802438-6222

E-post: admin@saltvattensguiden.se

Aktuell programversion

Invision Community 4.7.20

Tapatalk 2.1.1